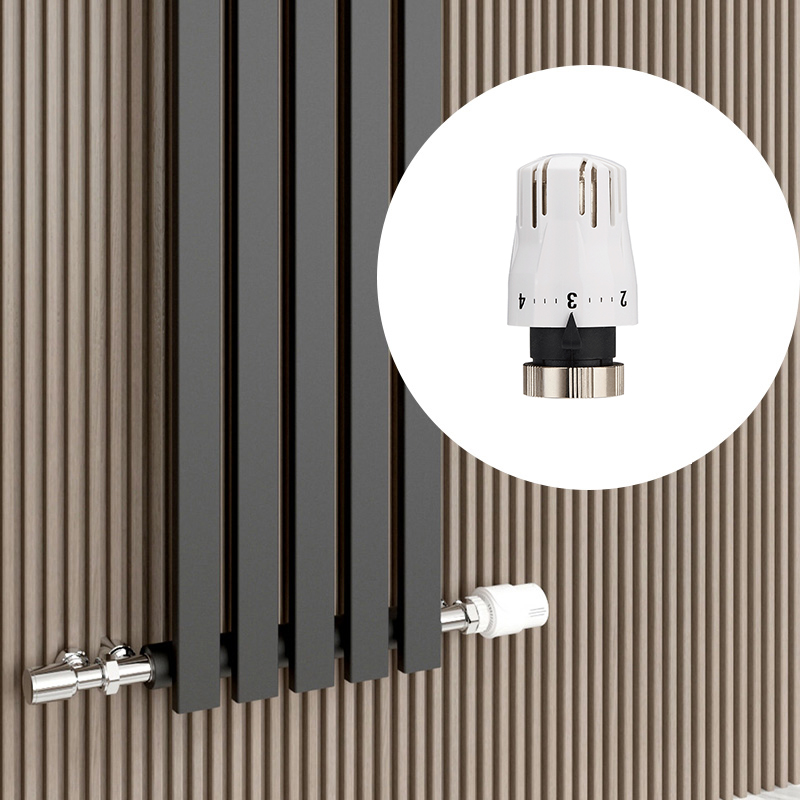

Mechanical traditional temperature control valve head is a kind of automatic temperature regulating device widely used in heating system such as radiator, floor heater manifold and so on. Its core adopts wax temperature package (or liquid expansion type) temperature sensing element, through the principle of thermal expansion and contraction to drive the valve spool opening and closing, without electricity to achieve independent temperature control, with a simple structure, stability and durability, economic and other characteristics.

Core Advantages

Pure mechanical structure, stable and reliable

No need for power supply or battery power, relying on the physical principle of thermal expansion and contraction, without the risk of failure of electronic components.

Suitable for old districts, rural self-built houses and other scenarios where the voltage is unstable or cannot be wired.

Anti-electromagnetic interference, can still be used normally in a strong magnetic field or humid environment.

Convenient installation, strong compatibility

Standard M28×1.5mm, M30×1.5mm and other threaded interfaces, adaptable to most radiator valves (e.g. Danfoss, Senville and other brands of valve body).

No need for professional tools, manual rotation to complete the installation, ordinary users can also replace their own.

Some models support manual adjustment of the spool stroke (such as 4mm/6mm), suitable for different system pressures.

Energy saving and environmental protection, reduce costs

Automatically adjusts the hot water flow, reduces the heating output after the room temperature reaches the standard, avoiding energy waste.

Compared with manual valves, it can save 10%-20% of gas or central heating costs.

No electronic waste generation, in line with environmental requirements.